Diesel truck collision repair poses unique challenges due to complex diesel engines and demanding bodywork requirements. Top workshops invest in advanced equipment like welding machines, CAD software, and precise paint systems to achieve accurate, efficient repairs. Skilled technicians with specialized training use advanced tools and diagnostic techniques to meet industry standards and preserve original quality and performance, as seen in Mercedes-Benz repair shops.

In the realm of automotive repairs, diesel truck collision repair stands out due to its specialized nature. This article explores the key elements that underpin success in this unique field, focusing on understanding the specific challenges posed by these robust vehicles, leveraging essential tools and technology, and recognizing the critical role skilled labor plays in achieving top-notch repairs. By delving into these aspects, we aim to illuminate the path towards reliable and effective diesel truck collision repair.

- Understanding the Unique Challenges of Diesel Truck Collision Repair

- Essential Tools and Technology for Optimal Results

- Skilled Labor and Training: The Cornerstone of Quality Repairs

Understanding the Unique Challenges of Diesel Truck Collision Repair

The world of diesel truck collision repair presents a unique set of challenges that differ from those encountered in standard car repairs. These trucks, often crucial workhorses for many industries, require specialized knowledge and equipment to handle their complex systems and structures. The primary challenge lies in addressing the specialized nature of diesel engines, which demand meticulous attention during the repair process. Unlike conventional gasoline engines, diesel engines have distinct design complexities that necessitate advanced diagnostic tools and a deep understanding of emissions control systems, fuel injection, and power generation mechanisms.

Furthermore, auto bodywork for these large vehicles poses its own set of hurdles. Diesel trucks often feature robust frames and cab designs, requiring skilled technicians to expertly straighten and repair panels while maintaining structural integrity. The need for precise alignment and restoration of original factory specifications ensures that only fully trained professionals can deliver top-quality car paint services and auto bodywork repairs, catering specifically to the unique demands of diesel truck collision repair.

Essential Tools and Technology for Optimal Results

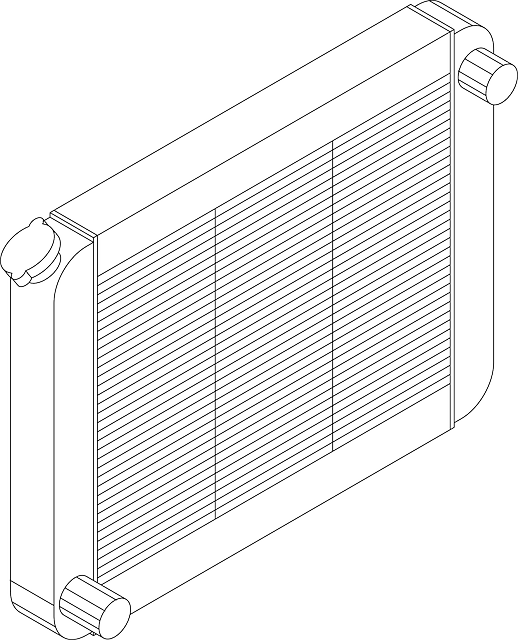

In the realm of diesel truck collision repair, having the right tools and technology is akin to having a symphony orchestrated for success. For optimal results, a well-equipped workshop is essential. Professional auto body shops specializing in diesel truck collision repair invest in state-of-the-art equipment that facilitates precise and efficient repairs. This includes advanced welding machines capable of handling heavy-duty steel, computer-aided design (CAD) software for accurate measurements, and high-tech paint systems that match the original manufacturer’s specifications perfectly.

Additionally, modern tools such as precision measurement tools, specialized hammers, and hydraulic presses play a pivotal role in restoring trucks to their pre-collision condition. These tools enable car body shops to navigate the intricate curves and contours of diesel truck bodies with finesse, ensuring that every dent is removed, every crease is smoothed, and every panel is aligned perfectly. This level of precision not only guarantees structural integrity but also restores the vehicle’s aesthetic appeal, making it a true testament to the skill and expertise of the auto body services provided.

Skilled Labor and Training: The Cornerstone of Quality Repairs

In the realm of diesel truck collision repair, skilled labor and comprehensive training are the cornerstone of achieving quality repairs. Expert technicians armed with up-to-date knowledge on the intricacies of diesel engines and modern vehicle systems possess the ability to navigate complex repairs with precision and efficiency. These professionals undergo rigorous training programs that cover a wide range of topics, from advanced welding techniques to the latest diagnostic tools. Such specialized education ensures that every repair meets not just industry standards but also the unique demands of diesel truck bodywork services.

For instance, consider Mercedes-Benz repair shops, renowned for their meticulous craftsmanship. The technicians here are not only experts in diesel truck collision repair but also adept at handling the intricate details and precise engineering of Mercedes-Benz vehicles. This level of specialized training ensures that repairs not only restore functionality but also preserve the vehicle’s original quality and performance, catering to clients seeking top-tier car bodywork services.

Diesel truck collision repair is a specialized field that demands a unique blend of expertise, advanced tools, and skilled labor. By understanding the specific challenges and implementing modern technology, repair shops can achieve exceptional results. Investing in well-trained technicians and up-to-date equipment ensures that every diesel truck accident is handled with precision and efficiency, ultimately enhancing safety and satisfaction for all parties involved.